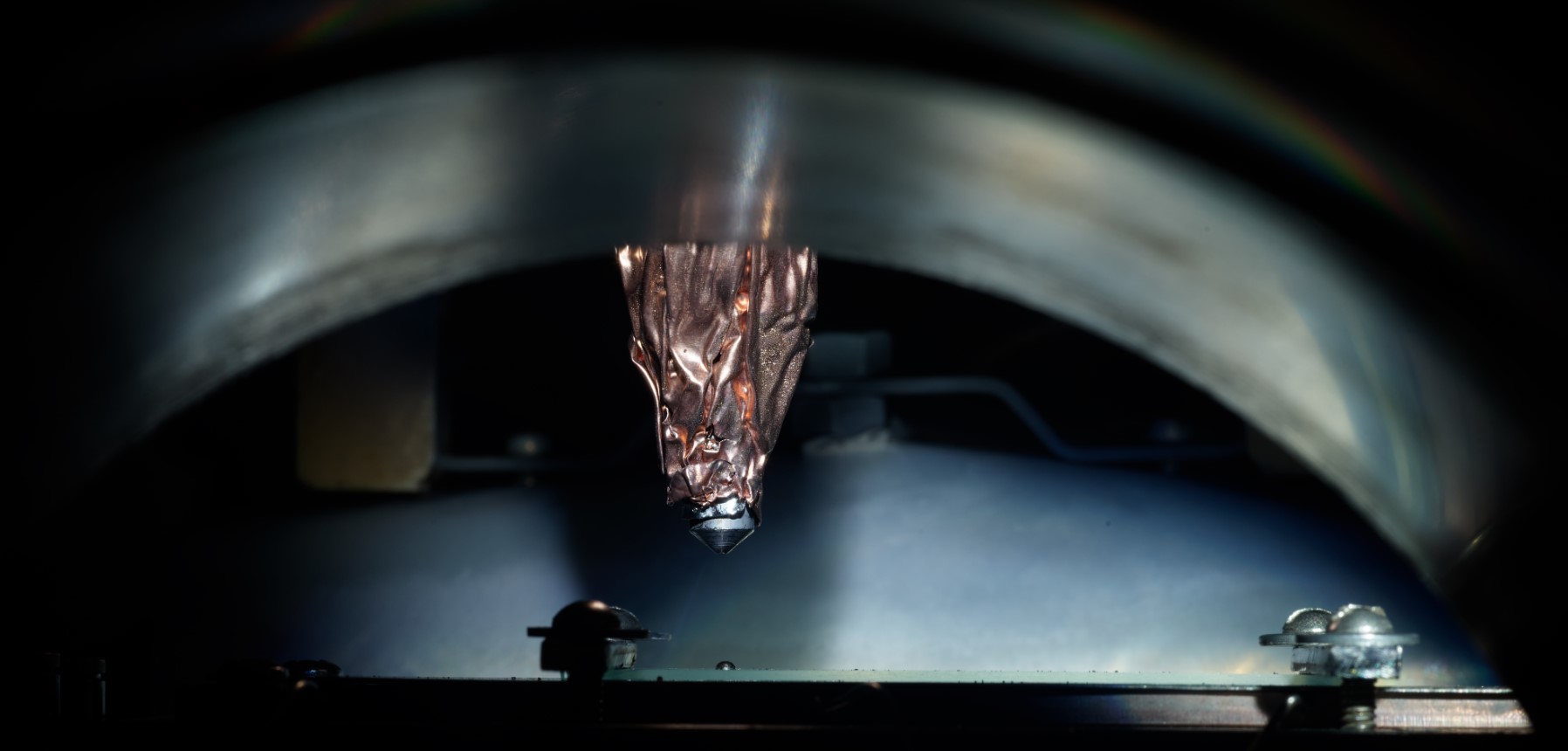

Materials Characterization and Analysis Test Stand (MCATS)

March 2, 2022

For proper functioning of lithium-based plasma-facing components (PFCs) control over the wettability of substrates must be known. The Materials Characterization and Analysis Test Stand (MCATS) chamber allows for rapid testing of lithium wetting on attractive materials over a large range of temperatures (200C – 750C). Material choice, surface roughness, and plasma treatment have all been shown to influence the lithium wettability. An understanding of these mechanisms and materials allows for the creation of components which can better control the flow of liquid lithium. For example, the nano-texturing of portions of a polished stainless steel plate may allow us to guide lithium flow on a flat plate with no need for physical walls. These techniques and experiences can be used to guide the fabrication of many lithium-based devices (PFCs, lithium injectors, lithium pumps, etc.).

Current work in MCATS is centered around ensuring that particular materials do no wet with lithium, such that if lithium is splashed on that surface, it will readily leave the surface. These tests are looking into many materials (metals, ceramics, polymers) that have application in fusion devices. Varying surface roughness and plasma treatment is being investigated to ensure that as a plasma cleans the surface or sputtering smooths the surface, a transition to wetting will not occur.