SHADE – Sputtering High-purity Atomic Deposition Experiment

February 27, 2009Sputtering High-purity Atomic Deposition Experiment (SHADE)

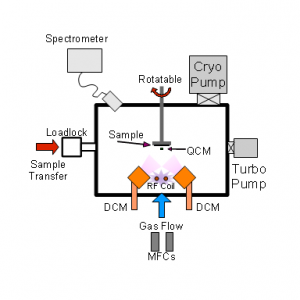

The SHADE chamber utilizes an ultra-high vacuum environment with a dual magnetron setup to deposit thin films and a secondary RF antenna in order to tailor the deposited film properties. SHADE is a valuable research tool allowing for a variety of sputtering targets to easily be exchanged and a loadlock system to transfer samples for deposition in and out without breaking vacuum.

Experimental Apparatus

SHADE is able to reach ultimate pressures in the 10-8 Torr range by using a turbomolecular pump as well as a cryo pump. However, operating pressures are typically between 1 and 20 mTorr with high stability through the use of two mass flow controllers (MFCs). Having two MFCs allow for multiple gases to be run simultaneously, a necessary ability for reactive sputtering.

SHADE is able to reach ultimate pressures in the 10-8 Torr range by using a turbomolecular pump as well as a cryo pump. However, operating pressures are typically between 1 and 20 mTorr with high stability through the use of two mass flow controllers (MFCs). Having two MFCs allow for multiple gases to be run simultaneously, a necessary ability for reactive sputtering.

Samples are transferred in and out of the chamber via a loadlock and gate valve system in order to maintain the integrity of the vacuum and to allow quick turnaround between experimental runs. Samples can be as large as two inches wide and still easily fit in the transfer mechanism. Once loaded into the chamber, the sample holder can be steadily rotated by a stepper motor in order to enhance uniformity during deposition.

Film thickness is monitored during deposition through the use of a dual quartz crystal microbalance (QCM). The QCM consists of two quartz crystals (one shielded and one exposed) which are oscillating at a very high frequency. As the exposed crystal receives deposition, the frequency slows down and the QCM interprets that as a film thickness. The shielded crystal is used as a check that any detected frequency change is due to actual deposition and not temperature change.

Film thickness is monitored during deposition through the use of a dual quartz crystal microbalance (QCM). The QCM consists of two quartz crystals (one shielded and one exposed) which are oscillating at a very high frequency. As the exposed crystal receives deposition, the frequency slows down and the QCM interprets that as a film thickness. The shielded crystal is used as a check that any detected frequency change is due to actual deposition and not temperature change.

The plasma is monitored by an optical emission spectrometer which can detect wavelengths in the range of 300nm to 2000nm. The intensity of specific emission lines are monitored to ensure that the plasma remains stable and can be used to adjust processing parameters to achieve optimal results.

SHADE can be equipped with either two two-inch or three-inch magnetrons, depending on the size of the s

SHADE can be equipped with either two two-inch or three-inch magnetrons, depending on the size of the s

puttering target being used. Whereas the two-inch magnetrons are a balanced closed-field configuration,the three-inch magnetrons can be either balanced or unbalanced and open- or closed-field through the use of interchangeable magnet packs. This allows for flexibility in plasma density and confinement.

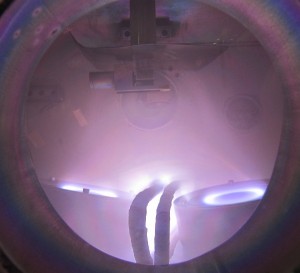

RF Antenna

When using the three-inch magnetrons, an RF antenna can be installed between them in order to create a secondary plasma besides the sputtering plasma. This secondary plasma increases the ionization of otherwise neutral gas and sputtered species which increases the sputtering rate and adds additional energy to the deposited film without significantly increasing the temperature of the sample. This additional energy allows for better film quality while maintaining a near room-temperature substrate. This high-quality, low-temperature deposition can therefore be used on plastic substrates which would otherwise melt at the higher temperatures required to achieve some high-quality films without a secondary plasma. Adjusting the RF power varies the power being delivered to the thin film and therefore the crystal structure of the film. Typical RF plasma power is 100-300W.

Research

With such a flexible system there are a several areas of research which have been explored. Previous research has developed Gibbsian-segregated alloys for use in semiconductor manufacturing optics. High reflectivity mirrors are needed in order to bounce the extreme ultraviolet light without intensity loss. These mirrors are prone to damage but by incorporating these specialized coatings they can become “self-healing” so that when they are contaminated, the contamination segregates into the bulk of the film while leaving the surface structure intact, and therefore reflective.

Current research using SHADE involves deposition of transparent conducting oxides (TCOs) such as Indium Tin Oxide (ITO) and Aluminum-doped Zinc Oxide (AZO). TCOs are a class of materials with an increasing presence in digital displays and photovoltaic applications. They allow light to be transmitted through them while still being able to conduct electricity. The most commonly used TCO is ITO but it has the drawback of using Indium, an expensive material with uncertain world reserves. Therefore alternatives are being sought, such as AZO, which can maintain the desired material properties but at a lower price. SHADE is being used to deposit AZO with the secondary RF plasma to achieve low-temperature deposition of high-quality films on flexible plastic substrates. The goal is to develop flexible photovoltaic sheets for low-cost power production.

Current research using SHADE involves deposition of transparent conducting oxides (TCOs) such as Indium Tin Oxide (ITO) and Aluminum-doped Zinc Oxide (AZO). TCOs are a class of materials with an increasing presence in digital displays and photovoltaic applications. They allow light to be transmitted through them while still being able to conduct electricity. The most commonly used TCO is ITO but it has the drawback of using Indium, an expensive material with uncertain world reserves. Therefore alternatives are being sought, such as AZO, which can maintain the desired material properties but at a lower price. SHADE is being used to deposit AZO with the secondary RF plasma to achieve low-temperature deposition of high-quality films on flexible plastic substrates. The goal is to develop flexible photovoltaic sheets for low-cost power production.