INOVA – Commercial Hollow Cathode Magnetron: Diagnostics and New Operation Modes

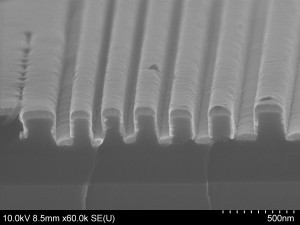

February 27, 2009There is a desire to create highly ionized metal fluxes by utilizing a extremely high-density plasma, facilitating near ideal IPVD required in filling narrow trenches of 32nm or less – realizing performance required for next generation of chips, produced using EUV(13.5nm) light.

A variety of plasma diagnostics can be used to study the detailed influence of parameter variation on the plasmas used for PVD and PECVD on a commercial 200mm INOVA high power (32 kW) hollow cathode magnetron deposition tool. Because of the intense deposition plasma conditions, non-standard geometry, and some non-standard frequencies used, specifically designed diagnostics are preferable to commercial solutions. These diagnostics include a 3-D scanning Langmuir probe, with analysis for magnetized plasmas to find the electron temperature and density. A self-cleaning in-situ plasma cup is being designed. To find the deposition rates and ionization fraction of the incident metal atom species a quartz crystal microbalance combined with electrostatic and magnetostatic filters will be implemented which will allow calculations of ionization fraction and system efficiency.

Based on the plasma diagnostics results, different processes were selected to study the sputtering deposition of thin films. Ta or TaN were deposited in an Ar or Ar/N2 sputtering plasma respectively, on the planar Si wafers and in Si trenches of different aspect ratios. The effects of ionization fraction, pressure among other parameters on the films quality and trench filling conformity are being investigated.

https://youtube.com/watch?v=tKD6t_QdPoM%26amp%3Bhl%3Den%26amp%3Bfs%3D1